Advantages of Inconel 800 Flanges

What are Inconel 800 flanges?

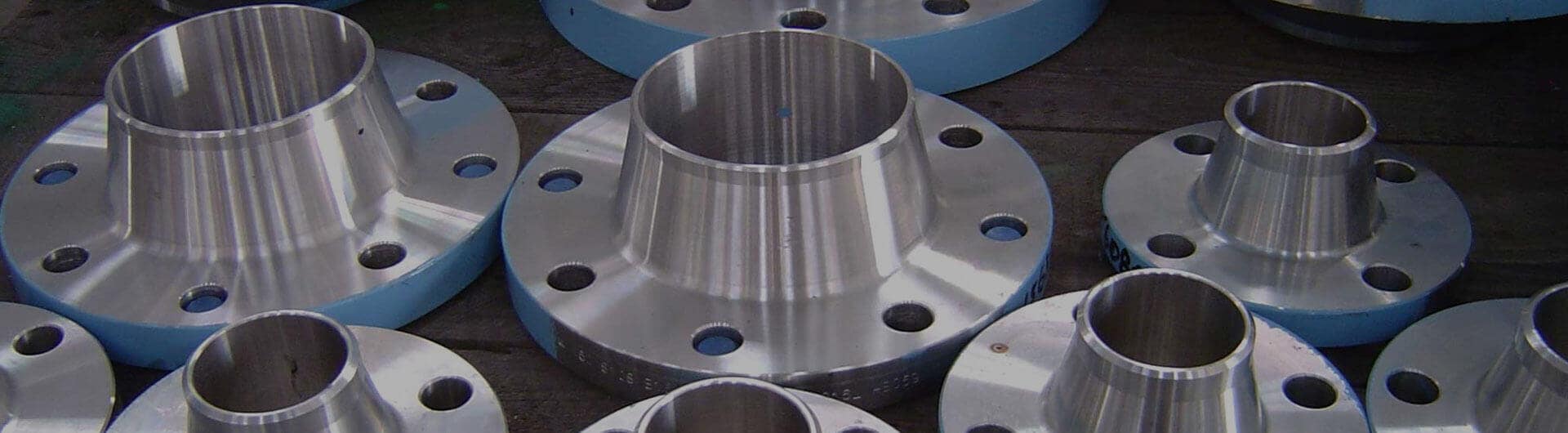

Flanges are crucial to the metal business, and Inconel 800 Flanges are great for several applications since they are resistant to oxidation. A high-alloy nickel-chromium alloy called Inconel 800 steel is used in numerous applications as a structural material. It is resistant to corrosion and oxidation, has a high strength-to-weight ratio, and can be heat treated at extremely high temperatures.

Inconel pipe flanges are used in industries like chemical processing because of their excellent resistance to sulfuric and hydrochloric acids. Due to its improved endurance and lower maintenance costs, Inconel pipe flanges are in higher demand in the fuel and water pipeline industries.

Characteristics of 800 Inconel flanges:

In terms of corrosion-resistant alloys, Inconel 800 flanges are among the most popular. Since it is reduced and partially oxidized, it exhibits a very high level of corrosion resistance. Also, there are only large sizes of fasteners available due to shortages. There are many types of Inconel Flanges, including slip-on flanges, blind flanges, Weld Neck Flanges, threaded flanges, and Inconel Flanges Reduction. Inconel is a super-alloy composed of nickel and chromium and is particularly austenitic.

Advantages of Inconel 800 flanges:

High-temperature applications benefit greatly from Inconel 800 flanges. They can endure heat up to 3,600°F (2,000°C) and are incredibly resilient. These flanges are resistant to mechanical stress, corrosion, and oxidation in addition to being able to handle extremely high temperatures. To create super alloys, alloys including the nickel and chromium alloy Inconel 800 are employed. These super alloys must be made in a way that prevents them from melting or burning at high temperatures since they are utilized in engines and power plants.

The ability of Inconel 800 to withstand corrosion is one of its greatest benefits over other materials. If exposed to salt water or coolant systems that contain sulfuric acid, which can cause corrosion on other metals, it won’t corrode or rust. Additionally, Inconel 800 has a relatively low thermal expansion rate, which means it won’t expand as much in hot temperatures as some other materials may.

Due to its great strength and resistance to corrosion, Inconel 800 can withstand extreme conditions like salt water or acidic environments like acid rain for many years without losing its consistency or durability over time. Oil and gas pipelines, electrical conduits, water, and wastewater treatment facilities, nuclear power plants, and even aerospace components can all be made with the versatile material Inconel 800.