Advantages and Applications of Hammer Union

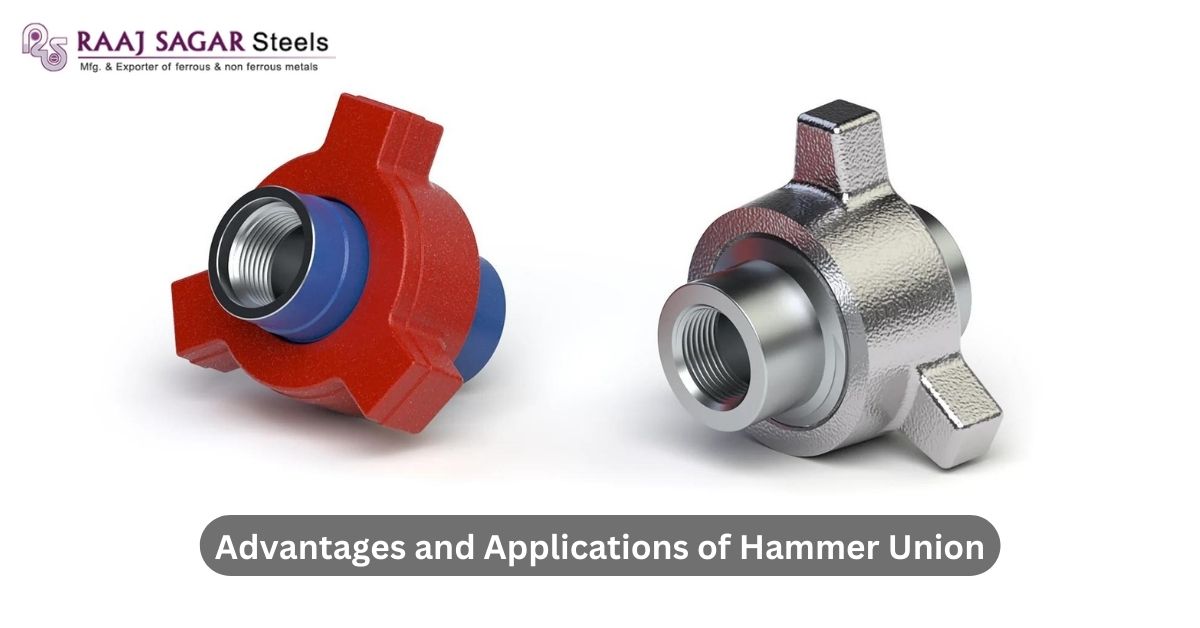

Hammer unions are constructed of strong carbon steel or chromium-molybdenum. For a long-lasting finish, the material is treated. The three pieces of a hammer union are as follows. They consist of the hammer nut and the male and female threaded components. Due to these components, the union may be quickly put together and taken apart. A unique rubber seal ring is another characteristic. These seals offer effective sealing with little torque.

About Hammer Union

A Hammer Union offers a quick and secure connection for hose and line pipes. It is a robust, high-pressure flow line connector used in the pulp, paper, chemical, and oil & gas sectors. Both their diameters and pressure ratings are extremely varied. They are frequently seen on marine dredging, oil, gas, and petrochemical vessels. In the chemical and energy industries, they are also employed. They are produced using forged alloy steel. At various temperatures, they have a high level of acidic Alkali resistance. They are strong against impacts and are easily machined. The forged steel hammer unions are more resistant to cavities and shrinkage. They come in a variety of worldwide standards. For various setups, they have varied colors. There are standards for them in DIN, IS, EN, and JIS.

Features

A high-pressure connection for threaded pipe is called a hammer union. This union type is used to carry different fluids and is made for higher-pressure applications. These connections can create non-leak seals and come in a range of sizes. For applications requiring rapid disconnections and connections, these seals are very helpful. Most of the time, premium raw materials are used to make hammer unions. These unions are made to handle extremely high pressures and come in various pressure ratings.

Advantages

Hammer unions are regarded as enduring and dependable, whether for short- or long-term uses. A Hammer Union is a powerful flow-line connector with a nut end, a threaded end, and a unique rubber seal ring. The smooth bore reduces turbulence and buildup, one of its benefits. Hammer unions come in wide different varieties. It has a nut end, which is the first kind. The variant with a threaded end is the alternative type. A split collar mounted on a second joint is the nut end in most cases. Commonly, a pipe is attached to a tank or other fluid storage vessel using the nut end of a hammer union.

Uses

There are numerous uses for hammer unions in the oil and gas industry. They are robust high-pressure connections made to reduce turbulence in fluid flows. They come in various sizes and pressure levels and are made from sturdy materials. They attach flexible hose assemblies and connect mud tanks to pipelines. They are frequently employed by oil and gas, ship mining, chemical manufacturing, and other industries. They are also utilized in numerous systems and pipelines. For usage in high-pressure situations, hammer unions of both types are created. In strip mining and marine dredging, hammer unions are frequently employed.